HOW BIOGAS SYSTEMS ARE DESIGNED

TO RUN ON YOUR DAIRY SLURRY.

Benefits of Farm Scale Anaerobic Digestion

1. Waste Management and Odor Reduction: AD provides a sustainable way to manage farm waste, reducing odors associated with manure storage and spreading, and lowering the risk of nutrient runoff into water sources.

2. Renewable Energy Production: By converting waste into biogas, you can produce your own renewable energy, reducing reliance on external energy sources and lowering your farm’s carbon footprint.

3. Income Generation: AD offers the potential to generate additional income through the sale of surplus electricity, participation in government incentives like the Smart Export Guarantee (SEG), or selling upgraded biomethane.

4. Nutrient-Rich Fertilizer: The digestate byproduct can replace or reduce the need for chemical fertilizers, improving soil health and potentially reducing input costs.

5. Environmental Impact: By capturing methane that would otherwise be released into the atmosphere, AD helps reduce greenhouse gas emissions, contributing to your farm’s sustainability and the UK’s climate goals.

Rapidly rising energy costs have meant that offsetting the farms energy costs with energy produced from the farms own slurry can be very cost effective. Our aim is to try and make the biogas installation at least cost neutral by reducing the farms electricity, heating, and fertilizer costs.

The returns you can expect to receive from your Biogas plant pay off because the cost of our specialist system designed for diary farms is less than competing systems. You’ll also produce green energy non stop and not be at risk to every increasing energy costs.

The Anaerobic Digestion (AD) plants from Biolectric, are designed specifically for diary farms and runs only on slurry, so there’s no need for any other additional crops. They are also automated so require less time maintaining.

The reduction of your CO2 footprint, reduction of CH4 in the atmosphere that the addition of a Biogas AD plant will create you will find the plant can be a useful credential to your own farm and your supply chain may approve of your use of green energy.

Your Biolectric plant could protect the farm from volatile energy prices and will make the farm more sustainable. Pressure to reduce emissions from livestock is coming through the supply chain and a Biolectric system would help reduce the farms carbon footprint

We’ve calculated that using your dairy slurry, the addition of a Biogas AD plant, can increase your milk value by up to 5p per litre for the next 20 years.

Using the slurry already available on your farm, there’s no additional noise or odours from the supply of additional crops, surplus or waste. The resulting slurry quality is greatly improved, produced locally, with no hidden transportation costs or emissions, is renewable and available for free.

Your Biolectric AD Biogas plant can add a secondary income through additional heat processes.

Build, install and commissioning is relatively simple and speedy. We can have a Biolectric AD Biogas System up and running in as little as 2 weeks!

WHAT NOW …

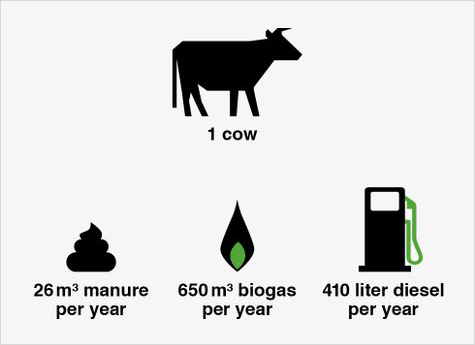

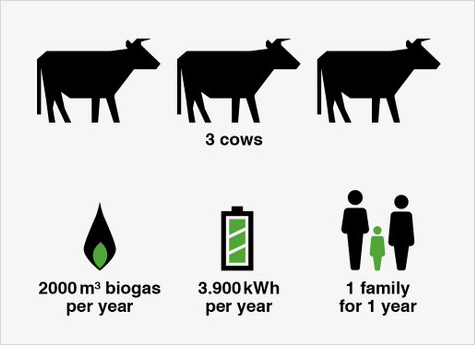

What do you need? At least 1500m3 liquid manure per year and about 200m3 of space on your farm or a minimum of 100 housed milkers.

What do you get from Biolectric?

Our expertise, knowledge and skill to take you through the funding options, FREE survey service , build, install and commissioning of an award winning, ready to use Biolectric micro AD digester with the capacity from 10kW to 74kW. Followed up with service and maintenance through the life of the system.

The Energy Produced

On a farm with 80 cows the yearly CH₄ emission of manure is equal to the CO₂ equivalent of 110 160 kg per year. By placing a Biolectric biogas installation this CH₄ (Methane) is converted into green energy and heat, enough to replace 110 cars off the road every year.

100+

EUROPE

INSTALLATIONS

110,160kg

ANNUALLY

CH4 EMISSIONS SAVED

110

EQUIVALENT TO CARS OFF

THE ROAD EACH YEAR

80

© 2025 Biolectric. All rights reserved

© 2025 Biolectric. All rights reserved